Coca-Cola – Digitalised filling down to the sensor

Predictive maintenance using ifm IO-Link sensors

Coca-Cola, the world’s largest beverage producer, operates over 50 filling plants in Western Europe alone. To address maintenance and faults quickly and precisely, the group is digitalising all filling systems and developing a digital twin for this purpose. This enables production processes to be monitored in real time and optimised immediately if necessary – even remotely, from anywhere in the world. Coca-Cola works closely with the automation specialist ifm to develop the necessary reliable sensors.

Edelstal in Austria is home to one of the flagship locations. “We are a licensed filling plant for Coca-Cola and fill almost all products here,” explains Christian Kohlhofer, Plant Manager, Coca-Cola HBC Austria. Filling over 500 million litres of beverages each year, the plant is one of the group’s largest.

“We are increasingly focussing upon automation and digitalisation. Much of what we implement is also later implemented by the group’s other plants,” says Christian Kohlhofer.

The plant in Edelstal also operates as a contingency plant: if production bottlenecks occur at other locations, the Austrian plant can step in to help.

Condition monitoring prevents unplanned downtimes

System availability is a top priority for the international beverage producer. “At our location, we pick up on every single system downtime immediately,” explains the plant manager.

The plant follows the principles of just-in-time manufacturing, rather than working to stock. This is why predictive maintenance with condition monitoring is so important. In other words, the condition of machines and systems is constantly monitored so that maintenance can be carried out exactly when it is needed. Real-time sensor data is used to promptly recognise wear, tear and other maintenance requirements. The aim is to avoid unplanned downtimes, reduce maintenance costs and extend the service life of the systems. Modern technologies such as IO-Link, IoT (Internet of Things) and machine learning enable maintenance work to be planned to take place at exactly the right moment – not too soon and not too late.

“The numerous installed sensors enable us to significantly increase system availability,” says a delighted Kohlhofer. “Maintenance is no longer time-based, but condition-based. This significantly reduces our costs.”

IO-Link sensors monitor complex processes

Sensors with an IO-Link interface are the first choice when it comes to digitalising systems. These intelligent sensors use a standardised, bidirectional communication interface to communicate with controllers and other systems. In contrast to conventional sensors, they not only enable the exchange of simple switching signals, but also of extensive process data and diagnostic information. Because the transmission of the measured values is digital and not analogue, it is also interference-free and accurate, as no conversion losses occur as with analogue transmission.

The sensors are easy to install and configure and provide precise data in real time. Acyclically retrievable diagnostic data such as minimum or maximum values, pollution degree or errors such as wire breaks or short circuits optimally support condition-based maintenance. IO-Link sensors also ensure high flexibility and efficiency in automation. Their high level of compatibility allows them to be seamlessly integrated into existing systems and easily integrated into the IT level through digital communication.

One example is the use of IO-Link vibration sensors in the can sealing process. “Quality in the can sealing process is a matter of thousandths of a millimetre,” explains Gerhard Wieszmüllner, Maintenance & Spare Parts Manager at Coca-Cola HBC Austria. “The ifm predictive IO-Link sensors enable us to detect the smallest vibration deviations and thereby guarantee a completely, permanently sealed can.”

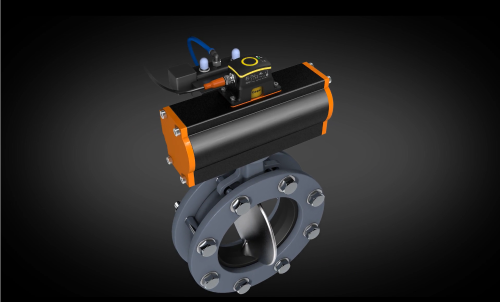

ifm’s IO-Link valve sensors are used on the bottle washing system flap valves. “We notice in advance if a flap seal is broken or needs to be replaced – without any loss of material,” says Gerhard Wieszmüllner. “This means, for example, that we don’t need to drain any alkaline baths and can thereby avoid protracted machine downtimes. This saves time and money.”

Picture 1: IO-Link-capable valve sensors not only detect the flap position, but also recognise wear, blockages or build-up on the valves, thereby supporting preventive maintenance.

Picture 2: LED signal lights provide a quick overview of the machine status on site.

Picture 3: A wireless vibration sensor on the circulating pump for reliable, intermittent monitoring of the total vibration in accordance with DIN ISO 10816.

When operating non-stop, unplanned downtimes can incur huge costs.

Decentralised IO-Link modules bundle the sensor signals while enabling a detailed insight into the digital sensor from the IT side, which allows for extensive diagnosis.

Digital twin via the Y path

All of the system’s sensor data is recorded in order to accurately assess the condition of the machines and their components. The Y-path is used to split the sensor data into two paths in real time: the first path transmits the data to the PLC, which handles the conventional control and regulation of the system. At the same time, the digital sensor data is channelled into the IT level via a second path. At Coca-Cola, the signals from the numerous sensors are automatically transferred in this way to the “Pocket Factory” IT platform. As a digital twin, this virtual image mirrors the real system exactly and is continuously updated with real-time data.

Digitalisation down to the sensor level gives Coca-Cola full transparency over its global production. The digital twin, based on data from ifm’s IO-Link sensors, enables condition-based maintenance of the systems. Machine learning and artificial intelligence are used to promptly predict wear, production errors and other anomalies in the process.

“This data enables us to carry out the right maintenance measures proactively and at the optimum time to ensure product quality,” explains Wieszmüllner. This prevents unplanned downtimes, minimises costs and guarantees high quality standards.

Another important aspect of digitalisation at Coca-Cola is sustainability. By using digital technologies, the group can reduce its ecological footprint. For example, the precise monitoring and control of production processes enables more efficient utilisation of resources such as water and energy. This not only benefits the environment but also helps reduce costs.

Cybersecurity requirements met

Cybersecurity plays a central role in a production plant such as Coca-Cola’s, as it is not only important to protect sensitive company data, but also to protect critical production processes from unauthorised access and manipulation. The increasing networking of machines and systems in Industry 4.0 increases the risk of cyberattacks on infrastructures.

A successful attack could not only result in production downtime, but also considerable financial damage or loss of reputation. Plants also often use systems that process production-critical data for quality assurance or to increase efficiency, for example. Protecting this data ensures that company secrets are safeguarded and processes run securely and stably. In a highly regulated environment such as Coca-Cola’s, all components, including sensors, must meet strict cybersecurity requirements to ensure the safe operation of the plant and the integrity of production.

“In collaboration with our internal cybersecurity team, ifm has found ways to comply with all standards,” praises Plant Manager Christian Kohlhofer. “Data is stored, processed and analysed in such a way that all cybersecurity guidelines are adhered to.”

Close partnership with ifm

Coca-Cola has been working closely with ifm as automation partner at its Austrian site for many years. Plant Manager Christian Kohlhofer praises this partnership: “ifm’s slogan is ‘Close to you’. This fits in with our company value ‘We over I’. We work together well and are both keen to find quick solutions,” says the manager. “ifm is always there when you need it and the response time is extremely fast when there are problems.”

Maximum transparency: The digital twin allows global access to the filling system right down to the digital IO-Link sensor. Anomalies are promptly detected.

Conclusion

Digitalisation and automation at Coca-Cola is an ongoing process that is steering the group into the future. By using state-of-the-art technologies and working closely with partners such as ifm, Coca-Cola can increase efficiency, optimise its production processes and ensure the quality of its products. Simultaneously, digitalisation is helping to improve sustainability and reduce environmental impact. The clear focus upon innovation and continuous improvement means the partnership between Coca-Cola and ifm is ideally equipped to continue successfully into the future.