ifm Web seminar

Simplified machine reliability with moneo Asset Health

Real insights for maintenance – seamlessly from hardware to software

What if your reliability and maintenance team could get real, actionable insights from your condition monitoring system?

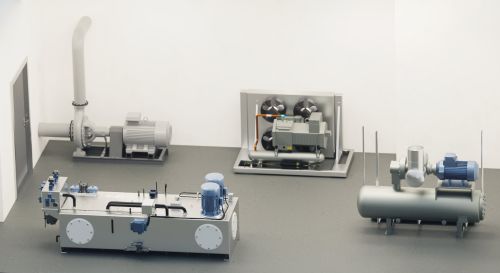

In our upcoming web seminar, we will show you how to move seamlessly from hardware to software with a simplified, intelligent solution. It automatically detects machine defects and identifies root causes in standard rotating equipment such as centrifugal pumps, fans, and electric motors.

With moneo Asset Health, you get a plant-wide solution that helps keep your equipment performing reliably and lifts your maintenance strategy to the next level.

What to expect in the webinar

- Current challenges in maintenance

- How ifm simplifies the digital maintenance transformation from hardware to software.

- What value you can get from moneo Asset Health with a quick live demo.

Ready to transform your maintenance strategy? Join our free web seminar and discover just how simple it can be.

Who should attend?

- Maintenance, Reliability & Production manager who want to reduce downtime

- End-user with focus on scalable maintenance planning capabilities

- IT and OT professionals looking for simple and secure IIoT solutions

- Anyone wanting to enter the world of Industry 4.0 benefits without barriers

Speaker

Matthias Betz has been working as technical manager and product manager at ifm for ten years. In this role, his focus has been on system integration and connectivity. Having established the IIoT business unit at ifm business solutions, he currently heads the product management team at ifm solutions and is responsible for the topic of connectivity. In addition, he coordinates cross-divisional edge computing products and IIoT concepts.

For over 6 years, Benedikt Obermaier has been working in product management for condition monitoring solutions. As Global Product Manager, he is responsible for defining all smart condition monitoring sensors and vibration sensors. He brings valuable experience in condition-based maintenance, vibration analysis techniques, and deep application know-how in the field of condition monitoring.