IO-Link vibration monitoring

Precise 3-axis measurement

The 3-axis MEMS technology offers precise measurements in all directions (axial, vertical, and

horizontal) from a single position.

Durable, maintenance-free design

The sensor’s robust stainless steel housing is maintenance-free, with a self-test function,

replaceable cable via an M12 connector, and an LED for device status monitoring.

Advanced condition monitoring

The integrated unbalance and bearing analysis feature, accessible via IO-Link, allows continuous

condition monitoring, detecting fatigue, friction, impacts, and temperature.

moneo IIoT devices

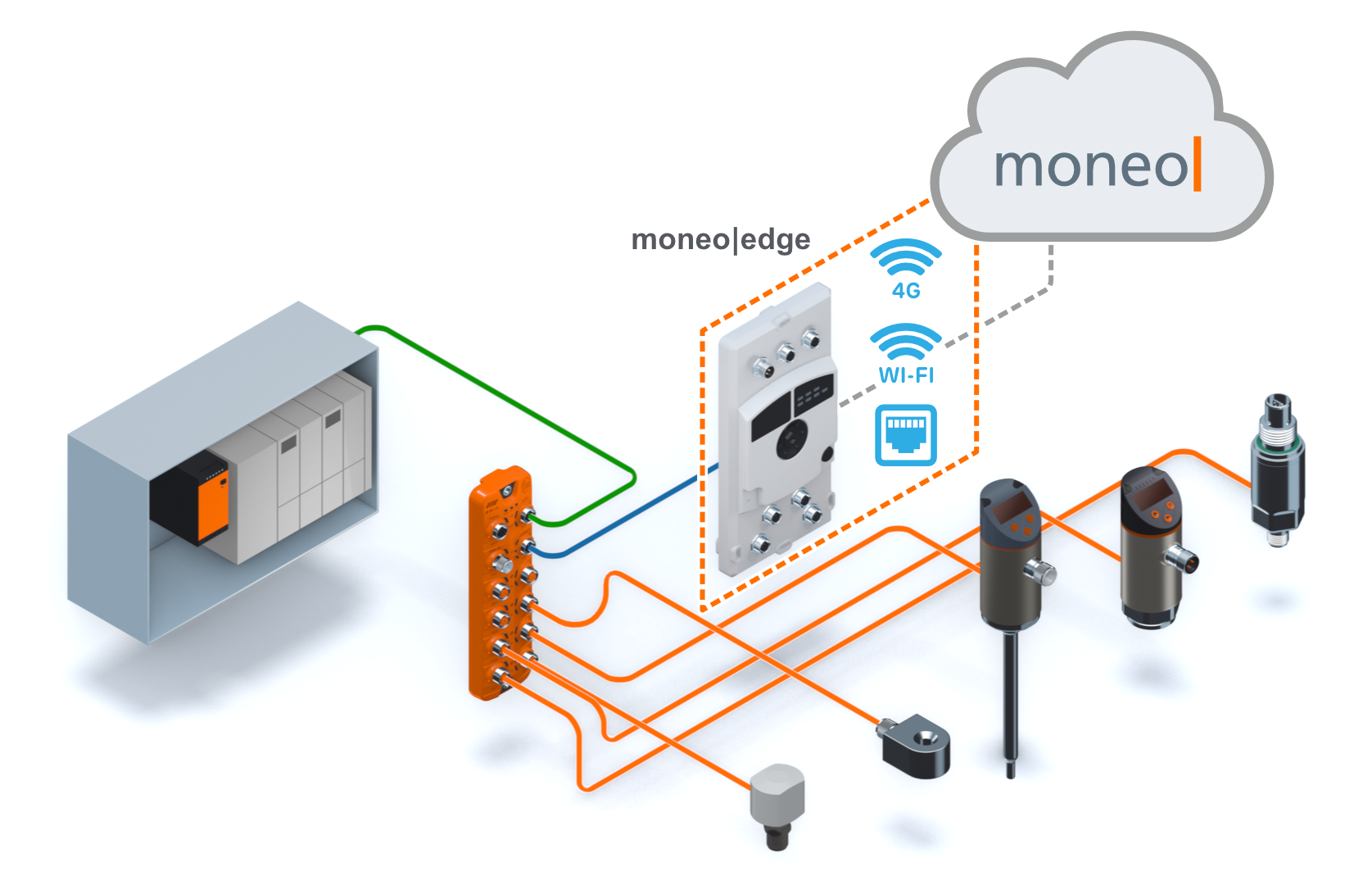

IIoT devices for data transfer and Cloud integration

IIoT devices are

essential for transferring data from sensors on the plant floor to the cloud.

These devices

include Ethernet field modules (IO-Link masters), which connect sensors, valves, and I/O modules to

an edgeGateway, providing secure communication to cloud platforms like ifm moneo Cloud, Microsoft

Azure, or AWS IoT Core.

The edgeController offers integration of system infrastructure with

IT, enabling cloud connection, visualization, or control functionalities. These devices ensure fast

integration, scalability, cybersecurity, and flexibility for both cloud and on-premises use.

Bluetooth connectivity

Secure wireless connection to sensors, masters, and connected devices.

What if you could access parameters, process values, and sensor diagnostics right

from the palm of your hand at the machine level?

ifm’s Bluetooth plug and the

moneo|blue app enable easy sensor replacement and parameterization without the need for a

laptop or computer.

Visualize process values for all devices connected to the same IO-Link

master, enhancing your ability to monitor and manage your system seamlessly.

moneo Cloud software

moneo IIoT core is a versatile software platform that supports seamless deployment either in the cloud or on-premises. It provides essential functions such as parameterization, data collection, visualization, and monitoring.

The platform enables quick setup for predictive maintenance and condition-based

monitoring to prevent unplanned downtime, empowering data-driven decision-making.

An additional feature, the Industrial AI Assistant, offers advanced AI-driven insights into machine

and process performance through automated analysis. It enables intelligent anomaly detection and

predictive analytics, supporting daily operations with an intuitive interface.

As a no-code

solution, moneo IIoT connects effortlessly to various industrial sensors, machines, and controllers,

providing a unified view of production environments and enabling real-time monitoring of machine

conditions, process parameters, and environmental factors.

Oil quality

Water ingress in oil can lead to plenty of different issues within applications such

as corrosion or wear of components, cavitation of pumps, poor filterability of oil or deterioration

of the viscosity.

Particle monitoring is the most effective real-time monitoring for

safeguarding oil systems and detecting mechanical wear. This technology enables users to assess the

effectiveness of filtration systems and track wear originating from equipment.

Precise

measurement

The LDH sensor accurately detects the moisture content and temperature of the

oil. This real-time data allows for proactive maintenance.

Easy installation

Thanks

to its standardized 1/2" NPT process connection and M12 electrical connector, the LDH1xx can be

quickly integrated into existing systems.

IO-Link technology

The sensor

communicates seamlessly with IT-based condition monitoring systems, providing valuable insights for

predictive maintenance.

Durable housing

The durable (IP69K) compact sensor has a

stainless steel housing, making it resilient in harsh operating environments.

IO-Link Master (A ports)

A gateway, or bridge, between smart IO-Link enabled devices and your control

system.

The DataLine master is the best choice for data collection and futureproofing your

machine with IIoT capability.

What if you could reduce machine complexity, increase capability, and save both

time and costs?

ifm’s field-mountable IP67/IP69k IO-Link masters leverage existing

communication in many sensors to increase accuracy, reduce build time, and minimize the number of

required devices.

Flow

Early detection of issues through flow monitoring

By analyzing flow

data of liquids or gases within machinery, abnormalities such as blockages, leaks, or irregularities

in pressure can be detected early, allowing for timely intervention before a failure occurs. This

proactive approach helps reduce unplanned downtime, optimize maintenance schedules, and extend the

lifespan of assets, ensuring more efficient and cost-effective operations.

Pressure

Prevent equipment failures with pressure monitoring

Unusual pressure

changes, such as drops or spikes, can signal potential issues like leaks, clogs, or wear and tear.

By continuously monitoring pressure, these problems can be identified early, enabling timely

maintenance before they lead to costly breakdowns. This proactive approach helps optimize the

performance of assets, reduce unplanned downtime, and extend the life of machinery, ensuring

smoother and more reliable operations.