Multiple point monitoring

Multipoint intelligent self-contained vibration sensors – VN series

ifm’s VN family offers more application flexibility than simple switches and transmitters.

- It measures overall machine vibration with a configurable frequency range up to 6000 Hz.

- The VNB211 is more powerful than simple switches and transmitters.

- It provides two flexible vibration measurements and onboard trend history as described below.

Two measuring channels

ifm’s VK and VT sensors measure only v-RMS and only at one point. The VNB211 has two measuring channels:

- Two characteristics can be measured simultaneously – velocity (v-RMS for overall machine protection) and acceleration (a-max or a-RMS for bearing wear / crash detection).

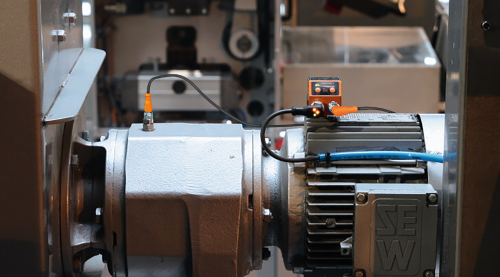

- The second measuring channel can be configured as an input for temperature monitoring, flow monitoring or a second vibration point (using VNA001 accelerometer) for the driven and non-driven ends of motor, for example.

- This flexibility can solve most applications.

4-digit alphanumeric display

The VN family can be configured using software or via the pushbuttons on the sensor display.

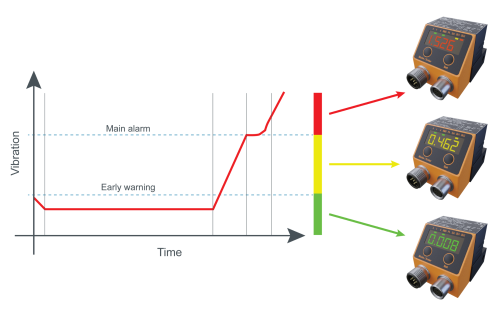

3-color (green, yellow and red) display gives at-a-glance indication of status.

On-board history

The VNB211 has on-board memory with real-time clock to store values at a preset interval. This information is configured and accessed via software. The maximum value detected during the interval as well as the average value during the interval can be tracked for trending and root cause analysis.

Maximum value detected during the interval and average value during the interval can be tracked for trending and root cause analysis.

The VNB211 can detect vibration increases caused by defects such as:

- unbalance

- misalignment

- looseness (velocity monitoring) as well as bearing wear

- machine crash

- gear problems

- pump cavitation (acceleration)