When quality is a matter of millimetres

How ifm’s PMD Profiler ensures quality in car body manufacturing

Resistant to extraneous

light up to 20,000 lux

Flexible, distance-independent

object positioning

Quick set-up

No expert knowledge needed

Results

- The PMD Profiler detects missing mats on body parts

- Resistant to extraneous light and easy to position

- Simple set-up in just a few minutes, no expert knowledge required

- Improved quality – costs savings through lower scrap levels

- High process reliability, no false alarms due to deviations of the object position

The challenge

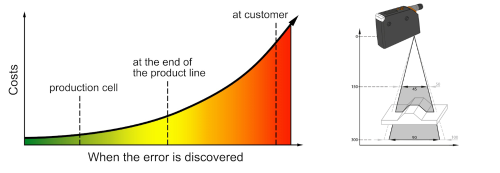

There is a simple principle in quality control: The sooner errors are discovered, the better. Errors discovered late usually lead to higher costs and more rejects.

At our customer’s body-in-white facility, a 1.3 mm rivet mat is manually glued to a body part in order to reduce noise inside the vehicle. If the mat is missing, the noise level in the car is too high – a no-go for a premium manufacturer. If the error is not discovered until later in the process, e.g. in the paint shop, the scrap rate will be considerable.

Quality control of this manual step proved difficult in the past. Because the mat is so thin, measurement with diffuse lasers can be unreliable. Errors were sometimes not discovered or false alarms were triggered. In addition, checking the correct orientation of the mat is not possible with this approach. Quality assurance with conventional 2D image processing was also ruled out due to the extraneous light in the production hall reducing the detection reliability.

The solution – why ifm?

The premium car manufacturer already uses various photoelectric sensors from ifm at their facility. However, many conventional sensors are not suited for this particular application, as a high immunity to extraneous light is required. In addition, the body part and the rivet mat hardly differ in colour and do not offer sufficient contrast for some methods.

The carmaker now uses the PMD Profiler from ifm that works by means of triangulation. The sensor projects a straight laser line onto the body part with the applied rivet mat. The laser light is reflected and detected by the sensor’s receiving element. There is an angular offset between the projection unit and the receiving element, so that the contour sensor can detect an object’s height profile.

Particularly helpful in this application: The proportions of the recorded height profile are independent from the distance between the sensor and the object. This makes positioning, installation and configuration of the sensor very easy. Neither external illumination nor screening against extraneous light is required. Reference objects can be taught via three pushbuttons and the intuitive menu navigation of the colour display.

After set-up of the PMD Profiler, an LED indicates whether the current part is OK. Via IO-Link, a digital signal can be transmitted to the PLC for direct processing. With the PMD Profiler, missing rivet mats are now immediately detected, and the body part can be fed back into the manual process. This solution prevents rejects due to missing or misapplied mats and allows our customer to reduce subsequent costs.