- MVQ smart valve sensors

- Applications

Applications: Reduce downtime and improve quality

Provide continuous position feedback of the valve actuator

The smart valve sensor provides precise position feedback and real-time process value via IO-link. The valve position is clearly visible from a distance using a 360-degree LED strip. The large window offers a mechanical position indicator that shows the valve position even when the power is off.

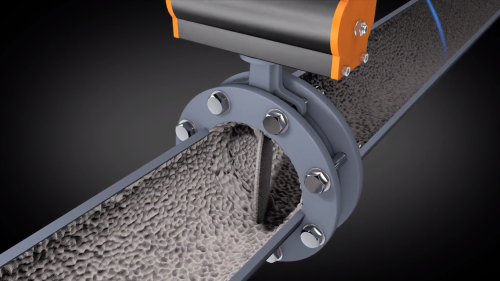

Detect seal damage

Seals inside quarter-turn valves become damaged over time. Chemical incompatibility between the seal and fluid causes seals to split or swell. Mechanical wear due to frequent valve cycling reduces the size of the seal.

Today’s manufacturing plants experience unplanned downtime when these seals are damaged and product leaks through the valve. In many cases, the problem isn’t detected until further downstream when the product is tested and quality is poor. This results in all in-process product to be scrapped. What if a sensor could predict when the valve will fail?

Detect build-up of foreign materials

Poor raw material supply quality, sticky or viscous media, a waste system that must accommodate solids/oils, or a corroded pipe can all prevent a valve from closing completely. The ability to monitor the closed position of a valve can save tens of thousands of dollars in scrapped material and downtime to replace the valve. Productivity and cycle time can also be affected as the time to close the valve increases with build-up.

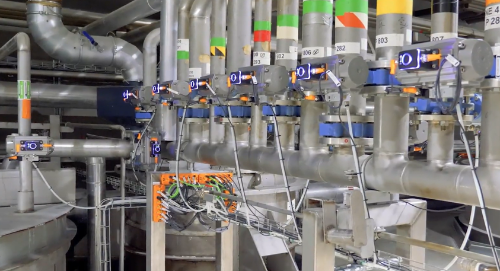

Simplify installation and increase efficiency with MVQ201

Installation of large valve islands becomes very easy when using the MVQ201, which directly controls the solenoid valve.

Solenoid-pilot design has gained popularity in recent years.

- High flow capacity

- Low power consumption

- More electrically efficient with faster response time

However, long cable runs from the solenoid to the control cabinet can be costly and time consuming to install. Tracing all the required cable runs makes troubshotting difficult.

With solenoid outputs from MVQ201 and an easy-to-connect M12 connector, a short cable can be used between to provide both power and direct control to the solenoid. This significantly reduces the cable management complexity.