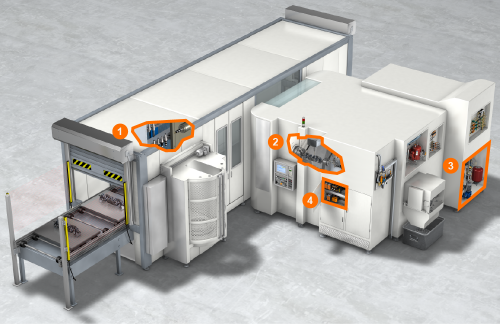

Machine tool monitoring

RtM monitoring systems can protect both production line availability and safeguard machine tools from extensive damage.

- Spindle issues -- unbalance and bearing wear

- Inadvertent crashes

Machine health status, process quality measurements and crash mitigation are all possible with ifm's VSE machine tool vibration edge controller systems.

Process monitoring

- Track and monitor cutting tool performance for worn tool replacement and equipment protection.

Product quality

- Monitor machining process to prevent rework and product loss due to out-of-tolerance dimensions and finishes.

Spindle condition monitoring

- Accelerometer monitors bearing frequencies alerting to damaged or worn bearings that can cause out-of-tolerance dimensions and finishes.

Spindle crash monitoring

- Accelerometer monitors peak forces to de-energize axis drives within 0.65 msec.

- Mitigates crash damage to spindle, tooling and workpiece.

Record and time stamp events

- Capture operational usage to pinpoint operating stresses that cause damage and wear.

Coolant system

- Monitor coolant systems for flow and temperature to ensure proper operational conditions.

- Monitor coolant levels in tanks and pump-backs for proper delivery and spill prevention.

- Maintain proper system pressure to avoid component damage from over or under pressure.

Edge computing

- Vibration Edge controller processes sensor signals and evaluates operational status for real-time condition monitoring.

- Automates complex algorithms (e.g., Fast Fourier Transforms) at the edge, minimizing network bandwidth and server resources.

- Tracks and locally stores measurement trend history to simplify data management and transfer.

- Converts measured data values into actionable information at the point of use.

- Connects to industrial and business Ethernet system for simplified asset maintenance and operational management.