South West Water – Condition monitoring across the entire water cycle

How South West Water achieves its business goals with vibration monitoring.

South West Water provides reliable, efficient and high-quality drinking water and wastewater services for a population of around 1.7 million in Cornwall, Devon, the Isles of Scilly and parts of Somerset and Dorset. To meet the needs of its customers the company stores water in more than 20 reservoirs and treats it in around 40 water treatment works to produce drinking water for the region.

South West Water also operates 650 wastewater treatment works. Among them is the Marsh Mills facility on the outskirts of the city of Plymouth. Around one third of the wastewater of the city’s 230,000 inhabitants is treated here in several stages before being fed back into the water cycle. After initial mechanical treatment, South West Water relies on a biological treatment using the activated sludge process at Marsh Mills. Microorganisms decompose the organic substances dissolved in the water. "As these are aerobic microorganisms, it is crucial that sufficient oxygen is permanently added to the water so that the decomposition process can take place in the required quality," says Brendon Teague, Condition Based Maintenance Manager at South West Water. This task is performed by nine Roots blowers, which supply a large volume of air at low pressure. With a total power of 615 kW, they pump up to 390 cubic meters of air per minute into the activated sludge tanks.

Fans – an unjustly overlooked piece of equipment

"So far, each blower and motor were checked about once a month in terms of their need for maintenance. Nevertheless, plant failures between maintenance intervals could not be excluded, as bearing damage was either unforeseen or developed between the intervals."

Another problem exists in that the noise which could indicate deterioration of the motor condition cannot be heard from the outside. "The motors are soundproofed, so people can literally walk past them undisturbed. Perhaps this is also one reason why fans and blowers in the water and wastewater treatment industry are often overlooked, even though they perform a task that is just as critical as, for example, the work of the pumps used in the drinking water supply."

Brendon Teague finally decided to equip nine blower units in Marsh Mills with vibration diagnostics from ifm This first step is, therefore, logical and does not come as a surprise.

Air is pumped into the aeration basin via powerful blowers - up to 390 cubic meters per minute at Marsh Mills.

Condition monitoring: keeping an eye on the health of the plant

"I have been working with ifm for a long time to safeguard South West Water's plants against unforeseen downtime by using condition monitoring," says Brendon Teague. Together with his team, he has installed over 200 VSE100 evaluation unit devices, plus the acceleration sensors connected to it, in South West Water's water and wastewater treatment works.

The vibration monitoring system consists of acceleration sensors and an evaluation unit. The sensors – South West Water uses sensors of the types VSA001 – are positioned at relevant positions in the system and transmit the data to the evaluation unit, in this case the VSE100. The latter permanently evaluates information from up to four sensors and sends corresponding switching signals to the control system when limit values are exceeded. The data and alarms can also be transmitted to a central control room via an Ethernet interface.

Easier troubleshooting and maintenance planning remotely

By means of vibration diagnostics, the state of health of a machine is permanently recorded. Thanks to the monitoring of the occurring vibrations in the time and frequency range, incipient damage is registered at an early stage and can be analysed in real time by ifm's own software in a more detailed FFT analysis (Fast Fourier Transformation). As an exact frequency can be assigned to the individual plant components or damage patterns, the sometimes time-consuming troubleshooting on site is no longer necessary and maintenance work can be prepared effectively, even remotely. This drastically minimises the amount of work and downtime.

Sensors help to achieve the company goals

"It is a real benefit to have a central overview of the status of all relevant machines via the software and to be notified as soon as a value exceeds a critical limit," says Brendon. The site Maintenance Manager can thus quickly get an update of the situation, assess the need for action and, in an emergency, inform the maintenance team on site. "Condition monitoring in this form is already helping us to achieve the company goals relating to the environmentally friendly handling of water and wastewater.

By detecting damage at an early stage, we have often been able to react in time and thus avoid downtime and costly repairs. Overall, we expect that due to the implementation of condition monitoring, we can reduce the cost of maintenance and replacement of damaged assets on average by between £100,000 to £150,000 per year."

Condition monitoring: standard on newly installed machines

In order to benefit even more comprehensively from the advantages of condition monitoring in the future, South West Water has defined condition monitoring on pumps and fans as a technical standard. "Every new plant must be equipped accordingly with sensor and evaluation technology that can be integrated into our existing infrastructure. This not only creates more operational certainty for large, important treatment works, but also helps us to efficiently and effectively maintain the quality and keep everything in perfect condition at smaller treatment works in rural areas."

The future: collaboration via the IoT platform

As a further development step, Brendon Teague can very well imagine switching to the new ifm moneo IoT platform. With moneo, even complex sensor infrastructures can be easily mastered, while the optional moneo RTM module offers far-reaching possibilities for an even more comprehensive vibration analysis. "In combination with the new edgeGateways from ifm and thus the possibility of making the data available in a cloud environment, I would be able to share the relevant data even more effectively with my maintenance colleagues in the supply area, so that the maintenance quality and the reaction speed in the event of an alarm would again increase significantly."

Vibration sensors on the blowers motors detect initiating defects well before major damage occurs.

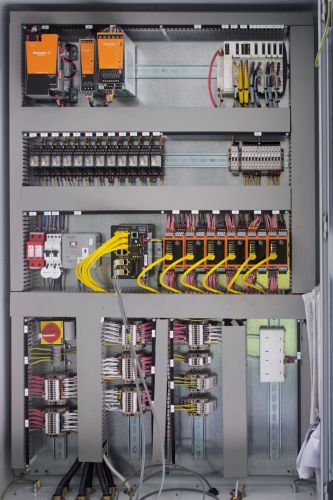

South West Water uses around 200 VSE100 evaluation units to monitor the machines in its water and wastewater treatment plants.

Conclusion

South West Water has been able to effectively prevent serious failures of critical water supply and wastewater treatment equipment such as pumps, centrifuges and fans with their comprehensive condition monitoring system. This saves the company significant costs for repair or replacement of equipment. At the same time, plant monitoring supports the company’s goals regarding the responsible use of water as a resource.