- Real-time maintenance

- Vibration

- Product platforms

- Programmable edge controller

Programmable edge controllers

Fault mode digital twin modeling

The power of edge computing is that the measurements and calculations are done at the point of use. These calculations convert raw data into narrow band root cause measurements. This creates a digital twin of the equipment’s fault mode kinematics. The equipment’s failure mode digital twin measurements are continuously computed in fractions of a millisecond.

Monitoring with root cause feedback in Real-Time

Real-time mathematical modeling at the edge eliminates bandwidth issues by converting large sets of raw data, into much smaller calculated root cause information. ifm’s VSE system simplifies creation of digital modeling by creating specific broad band and narrow band vibration indicators that continually monitor targeted machine components for maintenance and machine dynamics for production process quality.

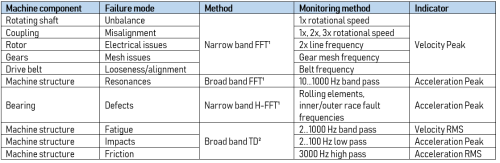

Typical machine monitoring model

The chart below shows a typical configuration for vibration monitoring of rotating equipment. Click on the magnifying glass to enlarge the chart.

FFT¹ = Frequency domain; TD² = Time domain

Effective management of online resources

Edge computing technology effectively manages your system network resources. ifm’s VSE edge controller can convert raw accelerometer measurements (25k points/sec) into usable information (up to 104 specific measurements). This compression is required to transmit data over system networks. Minimizing impact on network resources, computing power, data storage, and evaluation labor is vital for any large-scale rollout.

System integration

Integrate edge controllers in a wide variety of ways. Once configured, easily connect their switching outputs to PLC inputs, stack lights, or any other switching or analog control system. The VSE system is also fully compatible with Industrial and PC-based Ethernet networks such as EtherNet/IP, PROFINET, Modbus, and TCP/IP.

Software and tools

VSE system is supported with our VES004 vibration software available free of charge from our download site. Using the VES004, you can

- Configure monitoring measurements

- Convert raw signal

- Analyze time wave form

- Analyze spectrum

- Gain access to the onboard measurement trend history. A typical installation provides an estimated 1 - 2 years of history.

The VSE is also supported through our software developers' kit with preconfigured APIs.

Applications

- Machine tool

- Multistage compressors

- Separators

- Centrifuges

- Gearboxes

- Complex machines