- 2D vision sensors

- Technology

O2D5 vision sensor technology

ifm's O2D5 family of industrial image sensors can solve a variety of error-proofing and inspection applications throughout the manufacturing process. The product includes a CMOS image sensor, evaluation electronics and integrated lighting in a compact robust housing. It provides reliable performance in production control using object and contour recogntion and BLOB analysis tools.

CMOS processor

ifm's O2D5 family uses a 1.2 MP (1280 x 960 pixels) CMOS image processor.

- Each pixel contains a photon that collects and amplifies light from the camera lens.

- Micro lenses on top of each pixel maximizes the photon contact.

- The photon accumulates an electrical charge proportional to the amount of light it receives.

- The electrical charge is converted to an analog voltage signal.

- The analog signal is transmitted to an A/D converter.

- The image processor evaluates each digital signal and assembles into an image.

CMOS image processors are easier, faster and less expensive to produce, making them the most common in the marketplace.

LED light sources

Choosing the right lighting to maximize contrast for each pixel is critical. The O2D family comes complete with integrated high intensity LED light sources in RGB-W (red, green, blue, white) and infrared.

Note that the image sensor is not a color sensor!

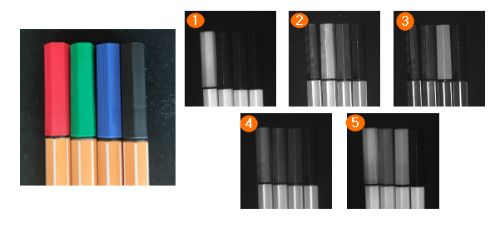

However, choosing a different color light source can have a dramatic effect on the contrast of the image. The image below shows colored pencils in daylight and the same pencils illuminated with the different LEDs of the O2D5 sensor.

1 = red light; 2 = green light; 3 = blue light; 4 = white light; 5 = infrared light

| Light type | Points to consider |

|---|---|

| Daylight (for reference only) |

|

| Red light |

|

| Green light |

|

| Blue light |

|

| White light |

|

| Infrared light |

|

Effect of polarization filter

It can be difficult to obtain sharp contours or areas on shiny objects because of reflections. The O2D5 sensors with RGB-W light sources include a polarization filter that can be turned on or off to minimize the effect of reflections.

1 = red light without polarization filter; 2 = red light with polarization filter

Object and contour recognition -- for objects with defined geometry

Contour evaluation and pattern match relies on identifying a sharp distinction between light and dark pixels based on a defined level of contrast. It analyzes shapes and captures the outline of an object.

The level of contrast can be adjusted in the configuration software to obtain the best contrast of the contour of interest. If the level of detail is too high, you probably see too many details. If the level is too low, you probably do not see enough details.

Set the level of contrast to highlight contours of interest

Contour detection is carried out by:

- Highlighting the contour of interest

- Optimizing the contour using filtering and elimination of unneccessary contours

- Saving this contour as the reference image

- Evaluating the live image and comparing the contour to the saved image based on a tolerance threshold.

Contour evaluation is ideal to Identify objects with defined geometry

- presence

- completeness

- position detection

- sorting

BLOB analysis -- for objects with variable feature

Binary-Logic Data Object is a set of pixels with the same logical state or level of brightness. Adjacent pixels are selected using a grey-scale histogram to obtain the best area of interest. It analyzes shapes based on the captured pixels.

The brightness level can be adjusted in the configuration software using a grey-scale histogram. If the level is too high, you probably see too many details. If the level is too low, you probably do not see enough details.

Set the brightness to highlight areas of interest

BLOB analysis is carried out by

- Highlighting the area of interest using a grey-scale value

- Optimizing the area using filtering and other tools

- Saving this area as the reference image

- Evaluating the live image and comparing the area to the saved image based on a tolerance threshold.

BLOB analysis is ideal to identify objects with variable features

- area

- relative size

- roundness

- contrast