Improve production quality through error proofing

pmd Profiler - Accurate contour analysis for quality control

- Improve production quality by checking every assembly step.

- Exceptional accuracy at the right price point allows for more error-proofing checks on production cells.

- A better alternative to complex vision systems for error-proofing checks.

- Reliable technology eliminates risk of false positives from external light or mechanical movement.

Assembly and error-proofing applications can be costly if not done correctly. Solutions for these applications range from single point lasers to complex camera systems requiring appropriate lighting.

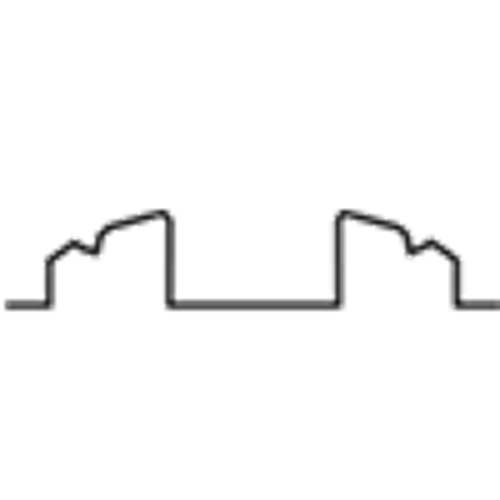

By projecting a straight laser line, the pmd Profiler determines the height profile of objects it inspects. It compares the height profile with the reference taught profile and helps you identify non-conforming parts in real time and reject them earlier in the manufacturing process.

At its simplest, the profiler is a point-and-shoot device that provides highly accurate pass/fail information. It is immune to extraneous light, so anyone can get up and running quickly with no prior experience.

Advantages at a glance

Set up in just a few steps

Set up in just a few steps• Quick connection with industry standard M12 cordset

• User friendly display and 3-pushbutton setup without software

Distance independent

Distance independent• High tolerance on object positioning

• Proportions of the object remain the same as distance to the sensor changes

Immunity to extraneous light

Immunity to extraneous light• Insensitive up to 20,000 lux

• No additional cost for external illumination or shading

Simple fault analysis with IO-Link

Simple fault analysis with IO-Link• Visualization of height using ifm Vision Assistant software

• Easily analyze errors and prevent them in the future

Cost effective alternative to camera systems and 1D distance sensors

The pmd Profiler reaches a whole new dimension in error control. Camera systems can be sensitive to external light and 1D distance sensors require precise positioning making alignment challenging. The pmd Profiler is unaffected by external light and it reliably inspects objects even at varying distances.

Transmit additional information such as reject rate or match value to your higher level plant network for trending and process optimazation.

| Application | Camera system | 1D distance sensor | pmd Profiler | |

|---|---|---|---|---|

| Sort by colors |  |

|||

| Sort by height |  |

|||

| Difficult ambient light |  |

|||

| Complex setup |  |

|||

| Shiny objects |  |

|||

| Variable alignment |  |

|||

| Contained object |  |

|||

| Uncontained object |  |

|||

| Dynamic application |  |

|||

| Contour detection |  |

|||

| Precision |  |

|||