- Cordsets for industrial automation

- Product testing

Reliability in various environments

ifm's ecolink product family undergoes rigorous testing for various environments. Explore the highlights of our product testing below.

Impact test

In the ifm impact test, connectors are exposed to extreme shocks. In addition to the individual components, the vibration protection of the coupling nut is tested. Only a coupling nut which permanently stays firmly in the optimum position guarantees the tightness of the connector.

Test definition -- 750 g velocity for 1 million shocks

Result

- Connection to sensor must remain tight

Flame retardancy

Products with approval for the US market must meet certain requirements regarding the behavior in fires.

Test definition - exposure to defined fires twice in 1 minute per UL746C

Results

- Connector must not continue to burn after external flame source is removed

- Connector must not be destroyed

Material compatibility

Connectors are exposed to increasingly harsh environmental conditions. New, more powerful bio oils, oils and coolants are brought on the market. Unfortunately, these products sometimes are very aggressive towards materials, in particular plastics. To meet these requirements, only materials which have been tested and which are of particularly high quality must be used. ifm carries out extensive tests with media currently common on the market. To shorten the test period, the test conditions by far exceed the usual operating conditions of the media.

Test definition -- Immerse cordset into medium for 1200 h at 80 °C

Result

- No swelling or deformation of the cordset

Drag chain suitability

Many applications in manufacturing plants require cordsets to withstand extensive flexing. ifm tests flexing and recommends a bending radius of 10 x the cable diameter.

Test definition

- Acceleration < 5 m/s2

- Travel speed < 200 m/min

- Horizontal travel length < 5 m/s2 for 5 m

- Vertical travel length < 5 m/s2 for 2 m

- Drag chain cycles > 5 million

Result

- No failure of connector, jacket or conductors

Electrical contacts

In addition to the general requirements such as volume resistance and insulation resistance, temperature resistance, electric strength and crimp extraction forces, the number of insertion/withdrawal cycles is an important characteristic regarding the quality of a connector.

Test definition -- 100 insertion / withdrawal cycles under defined test conditions, standard requires 0.2 Nm pin extraction force

Result

- 1.0 Nm extraction force (5 times the standard)

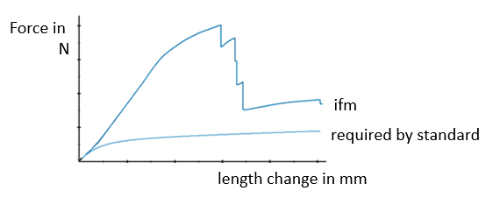

Tensile strength

In this test, the strength of the connection between the cable and the housing is tested.

Test description -- pull until destruction, standard is 100 N

Result

- 400 N for M12 ecolink cordsets

Placeholder