- Discover track and trace

- Solutions

- Access control

Access control: The right people at the right machines at the right time

Automating quality control and maintenance

Passwords get changed, lost, shared -- not a reliable means for machine access control. RFID technology is an easy way to ID people for proper machine access. The technology ensures the right people are at the right machine at the right time so critical assests are managed properly. IO-Link enabled readers make access control integration simple.

Realized improvements in operating efficiencies

Since the largest asset a production facility has is its workforce, optimizing the human element of your production is important. Machine access is a crucial element of access control, but secure and private serialization for the workforce can offer insights into additional training needs, or even eventual optimization to a specific machines where workers are most productive.

Increases in availability are realized by ensuring that only qualified personnel have levels of access to make significant changes to the machine setup or programming. Restricted areas can be locked by key access for personnel, and restricted areas can be secured with forklift access identification solutions. Optimization of personnel onto the machine they are most effective running can reduce scrap rates, and increase overall production.

- Prolong asset life by ensuring properly trained personnel are managing it

- Restrict access for operators, maintenance and engineering teams

- Gain transparency into your teams' effectiveness when running production

Increases in quality are realized by ensuring that properly trained personnel are setting up new production runs and making changes to the machine on the fly. Locking access to key areas of the systems environment assures that it is serviced by qualified personnel, and automatically records the changes that were made to production.

All of these factors allow for additional training when needed, and secure operation of equipment to reduce waste. Some personnel may produce less scrap on a particular machine, and their performance can be optimized in real time to increase efficiencies.

- Improve production quality and increase yields

- Reduce waste by ensuring qualified operators are running the equipment

Recommended product platforms

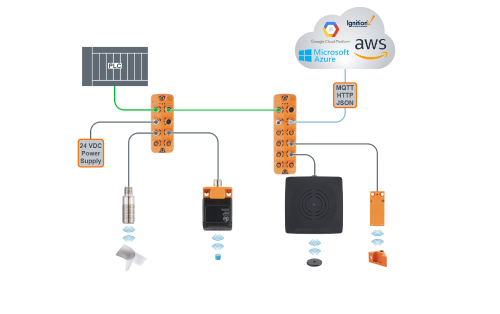

Multiple technologies can be applied to institute a robust access control program. Some are also beneficial for managing returnable assets among other functions. In many cases, it is beneficial for the solution to be able to simultaneously communicate directly to the local control system, and to a cloud based platform for operator access permissions and workforce optimization.

IO-Link HF system

These common requirements make IO-link HF RFID an ideal solution for access control. Adding an IO-link master to your machine also allows additional intelligent inputs and outputs for process data and OEE data collection points for part counting and quality assurance.

| Solution | IO-Link HF AL / DTI |

Modular HF DTE10 / ANT |

All-in-One HF DTE60 |

Modular UHF DTE930 / ANT9 |

All-in-One UHF DTE90 |

Gate tracking solution ZZ0818 | Image-based code reading O2I5 |

|---|---|---|---|---|---|---|---|

| Access control | +++ | ++ | ++ | + |

Click on the orange links to view product platforms