Technology

Like other ifm camera products, the O2I code ready is fully self-contained, including the imager, evaluation unit, illumination, and outputs. The evaluation algorithm provides 4x higher resolution for reliable reading results, 10x faster evaluation for high-speed applications, and 10x faster setup to optimize production availability.

The trend for image-based code readers is moving toward a “black box” solution with the ability to perform self- and application-diagnostics in real time without connecting to remote software. The O2I5 series includes powerful internal programmable logic to keep you informed…

- when your printer starts to run out of toner.

- when someone knocks the reader out of alignment.

- when your code starts to draw or skew.

These and many other logic function blocks are available within the Vision Assistant configuration software. To implement them, simply drag and drop the desired function blocks and interconnect them as appropriate.

Local device backup and cloning

Critical application and configuration data is saved locally in a removable flash drive, providing near instantaneous device cloning. When replacing a damaged sensor or cloning an application for a new location, commissioning time can be completed in less than one minute.

An integrated USB dongle stores up to 18,000 failed images for later diagnostics. Images can be stored with or without corresponding decoding, quality and time stamp data.

The reader is equipped with an integrated web browser for real-time remote access to configuration files, software, failed images and diagnostics.

The O2I5 family includes an electromechanical autofocus, which is optimized during the initial setup. Depending on the size and type of code, the depth of field can vary and still produce a readable code image. Internal testing has shown with autofocus completed at a distance of 200 mm, a ECC200 code and an EAN-13 code were both readable from 100…300 mm.

Configuration via smartphone app

A smartphone app (IOS and Android) is available for basic configuration of the device. IP address, trigger and other settings can be changed on the app. Then a data matrix code is created on the smartphone with the configuration. When this code enters the field of view of the reader, the parameters are automatically uploaded and saved to the reader.

Parallel alignment laser are used during teach / set-up to make finding codes easy. Laser pointers turn on automatically when using the Teach button. When using the Vision Assistant for set-up, the laser pointers can be toggled on and off in the “Images & Trigger” tab in the “Application” set-up screen. Simply place the code between the two beams.

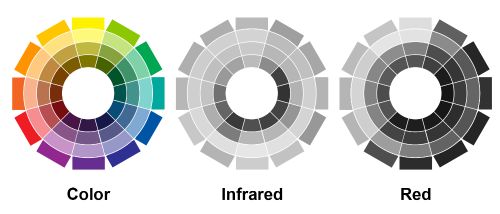

| Light type | Advantages | Disadvantages |

|---|---|---|

| Visible red |

Best solution for most applications, especially on printed codes with high contrast. |

Flashing red light, while not dangerous to personnel, may be unappealing. |

| Infrared |

Best suited for codes applied directly to parts such as dot-peened, engraved, etched, etc. |

Color independent, so entire image is washed out. |

The optional polarization filter built into the O2I5xxx readers ensures sufficient contrast to reliably read codes printed or dot-peened onto metal surfaces.

When light is reflected from a shiny object to a camera without using a polarization filter, glare can make the code difficult to read.

All light sources (1) emit waves in all directions. This is unpolarized light (2). When the light passes through a polarization filter (3), all waves are blocked except that in the orientation of the filter (4).

Within the Vision Assistant configuration software, the LEDs and polarization filters can be turned off and on to provide the most reliable image.

| The following codes can be detected and evaluated by the O2I5 family of readers | ||||

|---|---|---|---|---|

| Interleaved 2-of-5 | Codabar | EAN13 Add-On 5 | UPC-E Add-On 5 | GS1 DataBar Expanded |

| Industrial 2-of-5 | EAN8 | UPC-A | GS1 DataBar Omnidirectional | GS1 DataBar Expanded Stacked |

| Code 39 | EAN8 Add-On 2 | UPC-A Add-On 2 | GS1 DataBar Truncated | GS1 - 128 |

| Code 93 | EAN8 Add-On 5 | UPC-A Add-On 5 | GS1 DataBar Stacked | ECC200 |

| Code 128 | EAN13 | UPC-E | GS1 DataBar Stacked Omnidirectional | PDF-417 |

| Pharmacode | EAN13 Add-On 2 | UPC-E Add-On 2 | GS1 DataBar Limited | QR |

| Micro-QR | Aztec Code | GS1 ECC200 | GS1 QR Code | GS1 Aztec Code |