IO-Link vibration monitoring of fans in a central extraction system

The fans of an extraction system in the production hall are of crucial importance. Soldering vapours and fine dusts resulting from laser marking must be properly extracted. Otherwise, quality losses, health risks due to soldering vapours and a complete production standstill can be the result. Without monitoring of the fans, no preventive measures can be taken.

The starting position

At the beginning of the digitialisation project, there is no comprehensive, continuous fan condition monitoring. In the worst case, a defect detected too late will result in a complete standstill of the entire production area. A failure of this system means that

- product quality is reduced because fine dusts are not adequately exhausted during automatic labelling.

- machine defects and downtimes occur due to overheating if waste heat is not sufficiently dissipated.

- there are health risks for the production personnel as soldering vapours are not exhausted.

Goal of the project

Condition monitoring for fans with IO-Link technology

In order to permanently ensure product quality and to avoid machine downtimes and production losses, permanent, software-supported monitoring of the fans is to be implemented. This makes it possible to abandon inefficient, time-based maintenance intervals in favour of demand-oriented, flexible and predictive maintenance planning. Extensive condition monitoring is to be implemented using IO-Link technology. This also helps to protect the air quality for production staff.

Implementation

Due to the existing IT infrastructure, moneo can be installed directly on the existing hardware to activate the moneo RTM module.

In case of insufficient system capacity, the software package could have been made available alternatively on the moneo appliance. The moneo appliance is the IPC solution whose hardware components and computing power are precisely tailored to the software.

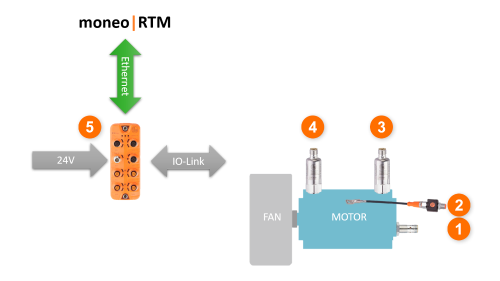

The fans are equipped with permanent vibration monitoring based on IO-Link. An IO-Link master is connected to the server via an internal VLAN. Via the IO-Link master, the data of the connected process sensors is transferred to the moneo software for evaluation.

Success

Increase in product and process quality through IO-Link vibration monitoring and moneo RTM

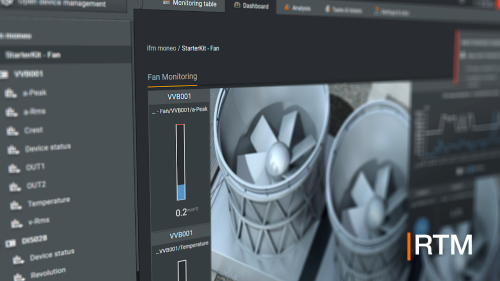

Extensive condition monitoring was implemented to optimise efficiency and maintenance. With the help of the modular IIoT platform moneo, fan monitoring has become more efficient and reliable. Thanks to the early detection of imminent damage to the fans, a failure of the extraction system can be prevented. In addition, necessary maintenance can be planned in such a way that plant downtimes will be reduced to a minimum.

System structure

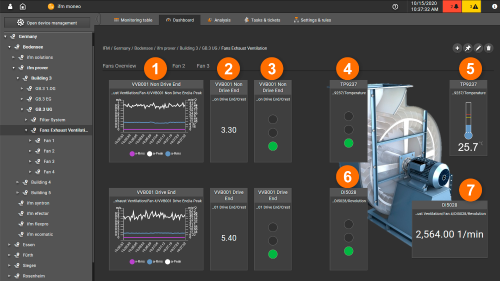

Dashboard

- Overview of vibration characteristics v-Rms, a-Peak and a-Rms in a line chart

- Crest factor (ratio a-Peak to a-Rms) for the assessment of the bearing condition

- Traffic light display of the crest factor (green = OK, yellow = > 10, red = > 12)

- Traffic light display of the temperature value (green = OK, yellow = > 50°C, red = > 60°C)

- Current surface temperature of the motor

- Traffic light display of the speed (green = OK, yellow = > 3000 rpm, red = > 3500 rpm)

- Current speed of the motor

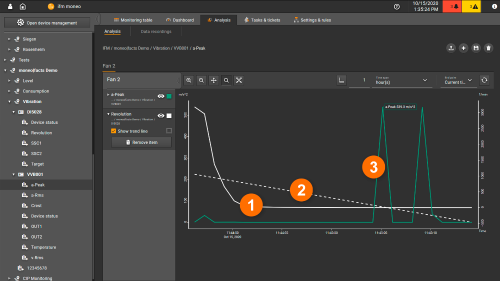

Analysis

From the analysis it can be deduced that the motor did not rotate when the peak occurred. This may indicate, for example, that it is a manually triggered fault.

Raw data recording (RTM Advanced Vibration Analysis add-on)

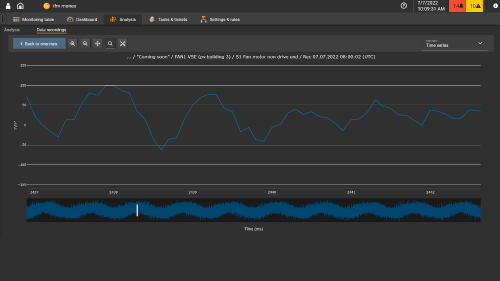

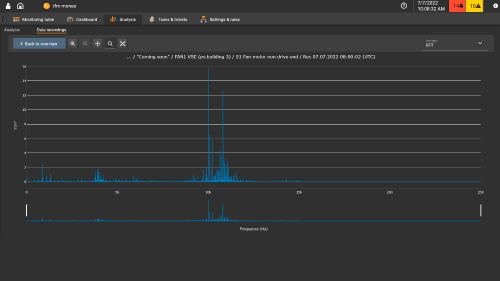

Recording of raw vibration data: moneo RTM can be extended via the add-on licence “Advanced Vibration Analysis”. This function is either time-controlled or responds to alarms from moneo RTM. The raw vibration data is automatically recorded. This can then be visualised in the time and frequency range.

This makes it possible to identify damage or anomalies and initiate timely maintenance. For advanced diagnostics, additional raw data files can be created that the user can download in various formats.

- Curve of the motor speed

- Trend in motor speed

- a-peak value of the VVB

Example: raw data recording visualised in the time range.

Example: raw data recording visualised in the frequency range (FFT).

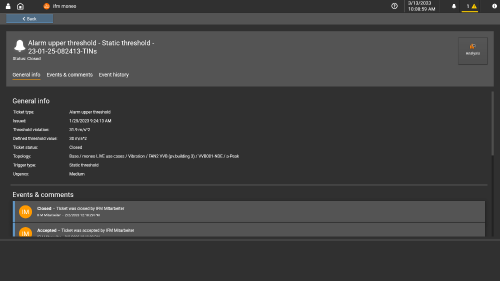

Ticket processing rules

As soon as a defined limit value has been exceeded or not reached, a ticket will be created for the corresponding process value. This can be taken over and processed by the responsible employee. Via the comment function, implemented measures and descriptions of solutions can be documented immediately.

Calculated values

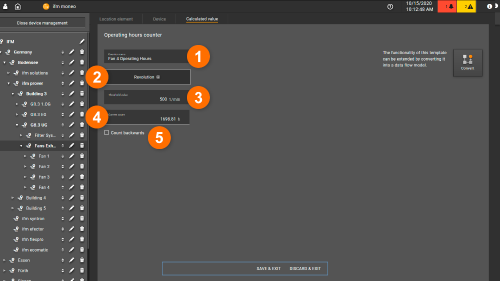

Using a template to calculate the operating hours, an operating hours counter can easily be set up by means of five options. In the case of a fan, the speed of the motor can be used as a measurement variable for counting up.

- Name of the operating hours meter for clear identification in the topology

- Data source used to count the operating hours

- Threshold value to define when the counter will count up

- Preselection of the current operating hours

- Option to count backwards