Vibration

What if your equipment could provide alarms before it fails? The detection and integrated evaluation of vibration signals serves as the basis for the seamless integration of online condition monitoring and real-time maintenance into automation and control systems.

- Eliminate unplanned downtime due to equipment failures.

- Monitor key machine condition indicators to predict and plan maintenance activities.

- Implement advanced real-time vibration monitoring without the complexity of traditional systems.

- Integrate easily into your process systems.

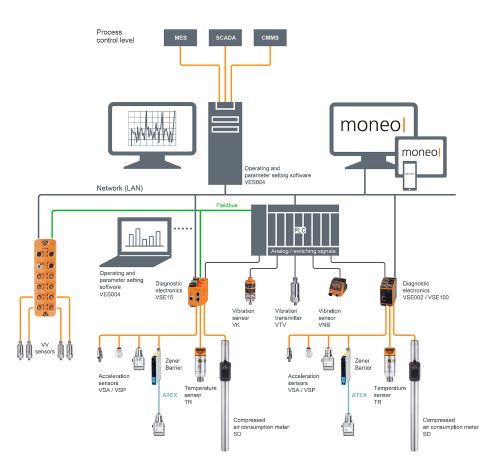

Systems for vibration monitoring -- from sensor to ERP (Enterprise Resource Planning)

ifm provides a wide range of vibration solutions from simple switches to fully programmable systems aimed at improving your machine uptime and overall profitability.

Which solution below best describes your application or machine? Click on the desired platform to learn more.

| Vibration sensor platform | |||||

| Single point | Multiple points | IO-Link monitoring | Programmable Edge controller | ||

| Application | Machines | VN | VV | VSE | |

|

Basic monitoring Simple machines, single switch / analog output |

Simple motors and fans | ++ | ++ | +++ | |

|

Multiple measurements and locations Multiple indicators for broad range of fault conditions |

Indirect driven fans and pumps | ++ | +++ | + | |

|

Multiple measurement Ethernet system Easy to deploy, multiple points, networking capability |

Blowers and simple speed reducers | +++ | ++ | ||

|

Complex machine and process monitoring Machines requiring multiple points with root cause capability and process monitoring |

Centrifugal compressors and machine tools | ++ | +++ | ||

Integration methods

Online condition monitoring and real-time maintenance can easily be added to your existing controls and network architecture. It can be upscaled as your needs change.