- Vibration sensor with IO-Link

- Integration

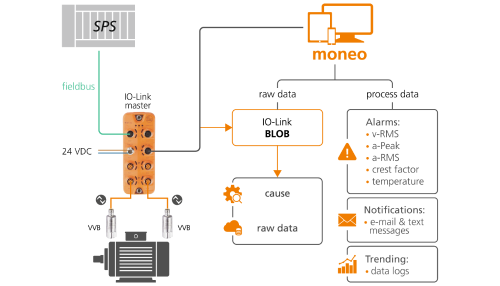

Integration of VVB into existing systems

Seamless integration thanks to IO-Link

Thanks to IO-Link, industrial grade machine protection integrates directly into your existing control platform. Field-compatible IO-Link masters transmit intelligent data to the controls and to higher-level IT systems. This intelligent data consists of the actual process values, but also of parameter data (identification of the measuring point, switch points, filters, units, etc.) and of diagnostic data (self-test, machine operating hours, sensor operating hours, device status or event counter).

Real-time maintenance with VVB and the IIoT platform ifm moneo

With it’s IIoT platform moneo, especially with moneo RTM, ifm offers a ready-to-use and powerful condition monitoring software. moneo RTM can be used to implement fully customisable dashboards for comprehensive plant monitoring and presentation of all important process data.

In case of damage, an alarm message is sent directly to the user. This makes it possible to react quickly and avoid a possible total failure.

Using the RTM Advanced Vibration Analysis add-on, the raw data records of the VVB sensor (BLOB) triggered by moneo RTM can be visualised in the time domain and the damage root cause can be diagnosed.

More integration examples

Vibration sensor

For integration into industrial equipment with switching outputs for indication or simple control

- 2 switching outputs (can be switched off), binary information (ON, OFF)

Possible characteristic values for the switching outputs:

- acceleration peak (a-Peak)

- average vibration velocity (v-RMS)

- average vibration acceleration (a-RMS)

- crest factor

- surface temperature

Network integration via IO-Link

For integration into existing:

- control networks (fieldbus)

- IT networks (Ethernet)

- cloud applications (Ethernet, MQTT, JSON)

Transmission of:

- process values (a-Peak, v-RMS,…)

- diagnostic values (e.g. device status, self-test, machine operating hours)

- event data (e.g. event history, event counter)

- parameter data (e.g. filters, switch points)

Integration of VVB with IO-Link into your PLC

Integration into your PLC via the common fieldbuses:

- Profinet

- Ethernet/IP

- EtherCAT

- Modbus TCP

As an option, the data can also be transferred to any SCADA, MES or company control system.

Transmission of:

- machine condition as condition value (= process values)

- alarm signals

- counter signals (calculation of component lifetimes)

- machine uptime based on the vibration

- raw data (BLOB)

Remote monitoring with VVB and io-key

- Fast integration at remote measuring points – plug & play – from sensor to cloud

- Initiate preventive measures through central monitoring in the cloud

- Minimum of wiring and wireless communication via the mobile network

Vibration monitoring via smartphone and IO-Link Bluetooth plug

- Quick and easy set-up

- Visualisation of characteristic values on your mobile device with the moneoblue app

- VVB parameter setting and monitoring directly in front of your machine in real time