SM Foodmag sanitary magmeter

Revolutionize your process control with reliable and accurate data

The SM Foodmag offers integrated flow, totalizer, temperature, conductivity, and

media detection measurements in one device, providing a comprehensive overview of your system. The

3.5" local display allows immediate access to flowmeter data, keeping you informed at all times.

Additionally, the onboard history function helps investigate process anomalies for quick issue

identification and resolution.

Streamline setup and commissioning

The guided wizard

simplifies programming, allowing you to set up and commission the magmeter in less than 5 minutes,

significantly reducing downtime.

Maintenance-free operation

The SM Foodmag comes with

factory-calibrated accuracy and repeatability, eliminating the need for field calibration. Access

your calibration certification easily via a QR-code on the display, ensuring compliance and ease of

documentation.

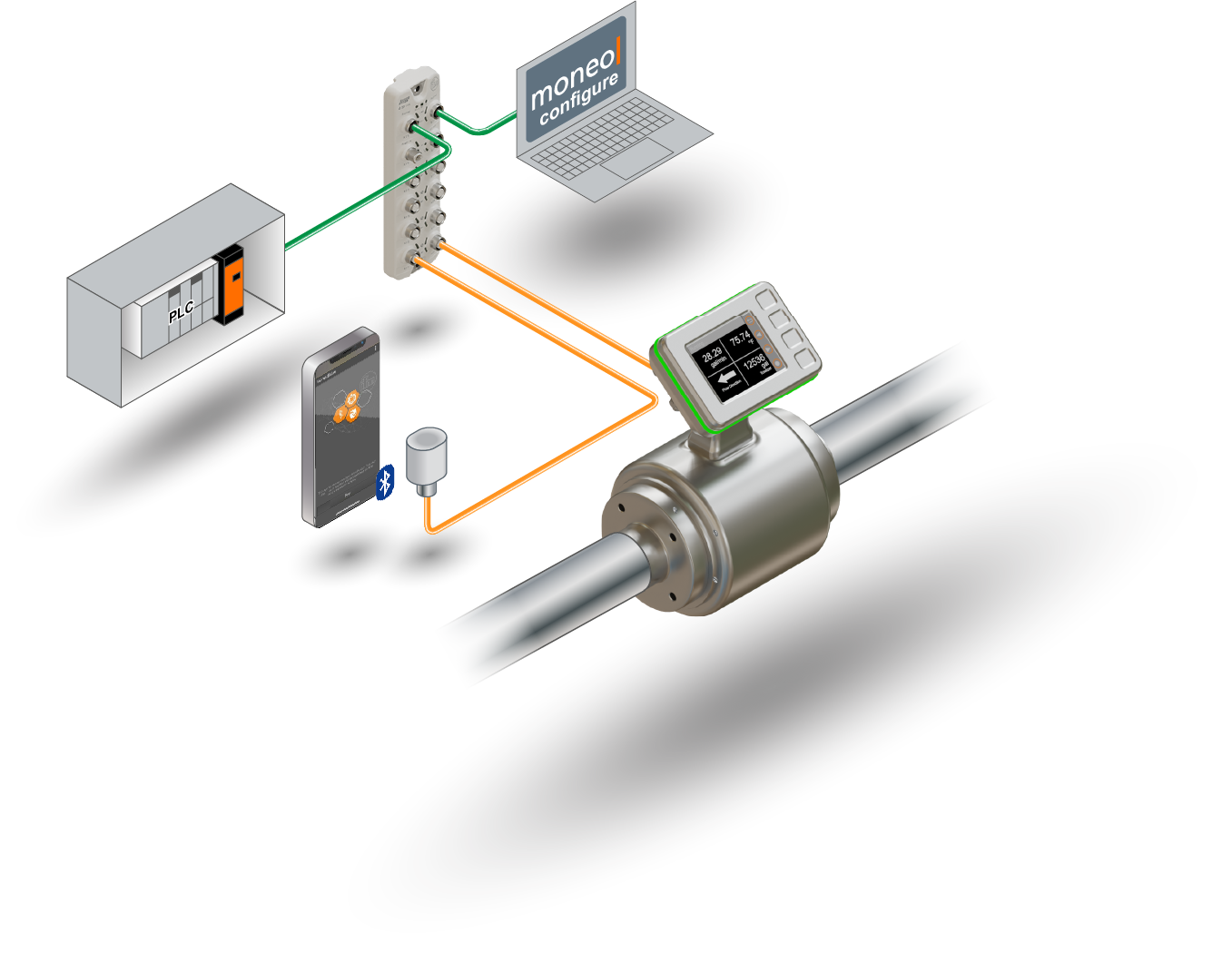

IO-Link benefits

Enhanced accuracy and efficiency

IO-Link's pure digital signal improves accuracy and resolution over traditional analog systems, ensuring precise measurements. One IO-Link sensor can replace multiple devices by supplying various process values over a single wire, streamlining your setup.

Simplified setup and maintenance

Bi-directional digital communication allows for rapid commissioning of field modules and IO-Link devices by simply uploading a configuration file, saving valuable time. Obtain "point of issue" location-based diagnostics directly on your system, enabling swift issue identification and resolution.

Seamless device management

Maintain your machines effortlessly with automatic device replacement and verification, allowing end users to swap parts easily and ensure continued operation.

Bluetooth connectivity

Secure wireless connection to a sensor or master/connected devices.

What could you accomplish on your next project if processing capacity, memory, and connectivity were unlimited?

Visualize process values and parameters for connected devices on the ifm IO-Link master on your smart phone free of charge for Apple and Android smart phones

Device configuration

A free software platform that allows for simultaneous update and configuration of all connected ifm masters and any supplemental IO link device.

With moneo|configure , any number of connected ifm masters and IO link devices can be configured and commissioned with a single click.

A visualization of process values and available parameters aids in troubleshooting and commissioning.

Robust design

Accelerate line changeover and cleaning

The SM Foodmag withstands CIP/SIP cleaning cycles at 150ºC, ensuring durability and consistent performance. The built-in conductivity measurement detects phase changes, reducing CIP cycle time and boosting efficiency.

Prevent unplanned downtime

- Robust and lightweight design: The lighter electronics housing reduces inertial forces in high vibration environments, improving stability and longevity.

- Chemical ingress prevention: The welded display with no exposed elastomeric seals safeguards against chemical ingress during cleaning processes, maintaining integrity and reliability.

- Reliable readings: The spiked electrode design ensures accurate readings even with fat and protein buildup, while the 3-point fluid detection measurement prevents pump cavitation due to empty pipes.

- Eliminate false readings: Solid state sensing technology eradicates the risk of false flow readings common with mechanical flowmeters.

The singular M12 quick disconnect for power and outputs streamlines setup. Reliable capacitive push buttons, unaffected by washdown environments, ensure ease of use and longevity.

IO-Link Master (A ports)

A gate-way, or bridge, between smart IO Link enabled devices and your control system.

The Data Line master is the best choice for data collection and future proofing your machine with IIoT capability.

What if you could reduce machine complexity and increase capability while saving time and expense?

ifm’s field mount IP67/IP69k IO Link masters leverage communication already available in many sensors to increase accuracy, reduce build time, and reduce required devices.

Wide application coverage

Adaptable to diverse media

The resilient PFA measurement channel and 316L stainless steel electrodes protect the sensor from chemical attack, ensuring longevity and reliability. Capable of reading media with conductivity as low as 5 µS/cm, it suits a broad spectrum of applications. The sanitary 3-piece design allows for different gasket materials, offering flexibility for each specific application.

Confirm CIP cleaning and eliminate contamination

The integrated conductivity measurement detects phase changes in process media, confirming CIP cleaning and preventing cross contamination of CIP media and product.

Power Supply

Single or multi-phase AC to 24V DC power generation for use in a cabinet or IP67 protection for use in the field.

How much would you save if you no longer needed to create a centralized cabinet for your controls system?

ifm has invested in the development of high protection ratings on all devices, meaning that you can choose to move everything to the field. Even your power generation.