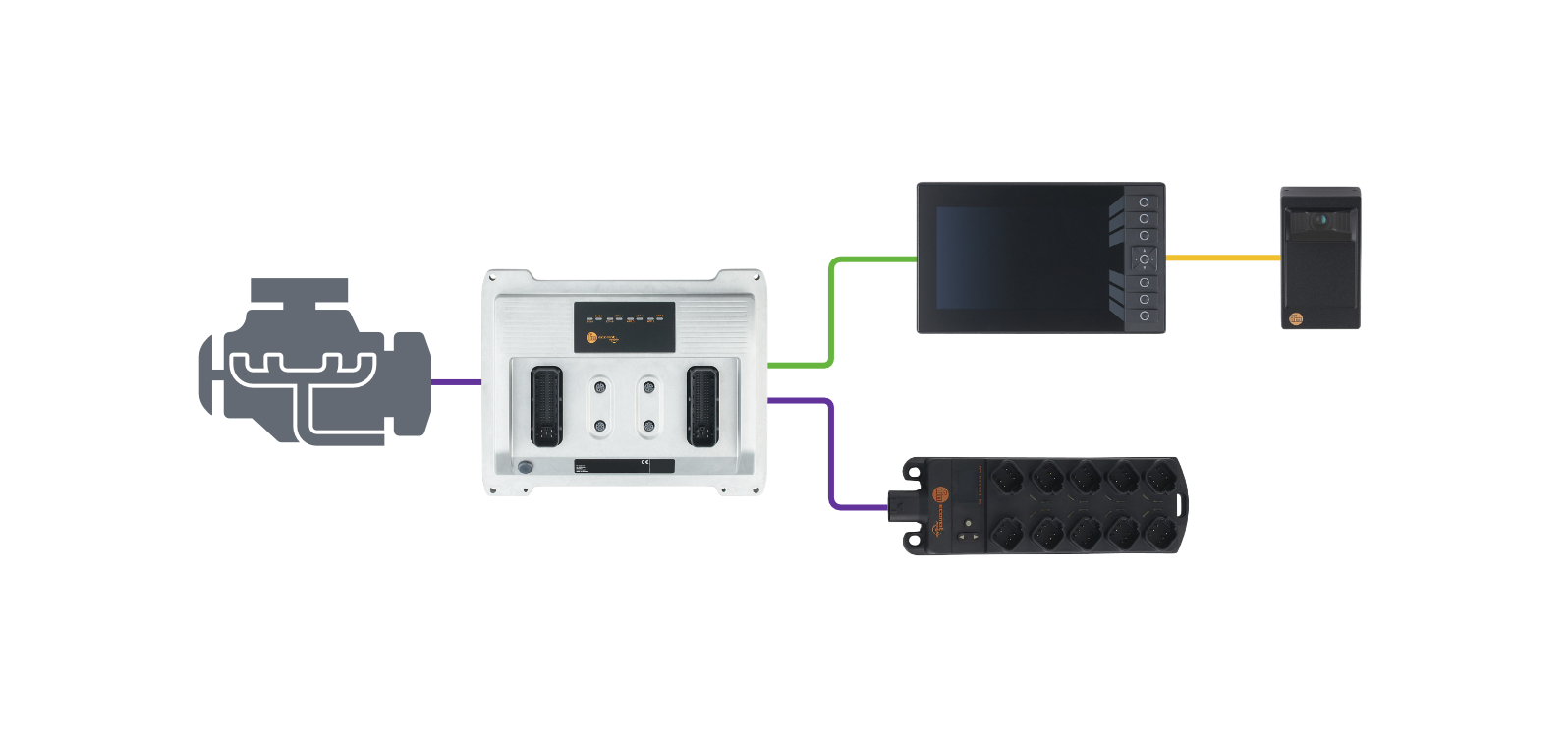

ifm hardware

Features

ifm's 3D mobile camera system enables machines to react to an obstacle before your driver sees it, automatically halt the vehicle when an object enters its path, and improve the speed of operation by avoiding collisions when approaching other vehicles.

- Reliable data provision via Ethernet UDP

- Fast response time with time-of-flight technology

- Suited for use in mobile machines

- Compact and robust housing

- Long sensing range up to 35 m