- moneo: IIoT platform

- Use cases

How moneo RTM optimises level monitoring in a calibration plant

Level monitoring on cold and hot water tanks

The calibration of flow sensors takes place in the calibration plant at ifm prover gmbh.

To ensure maximum measuring accuracy, both hot and cold water is sent through the sensors. The measured values are used for calibration.

The initial situation: visual inspection of the water level

In the past, ifm prover gmbh would determine the level of the water tanks daily by means of visual inspection by the employees. There was no visualisation of the current water quantity or any limit value monitoring with alarm function. As a result, the calibration process repeatedly came to a standstill in case of insufficient water quantities, which would lead to downtimes and, thus, increased costs. Due to the lack of data recording, there was no transparency regarding the refilling processes. Neither was it possible to determine the maintenance requirements and plan them in good time.

Goal of the project: implementation of an efficient refilling process

In order to avoid unplanned downtimes in the future, permanent, software-supported level monitoring was to be implemented. This was supposed to inform staff in good time of low water levels or maintenance requirements by means of warning and alarm signals.

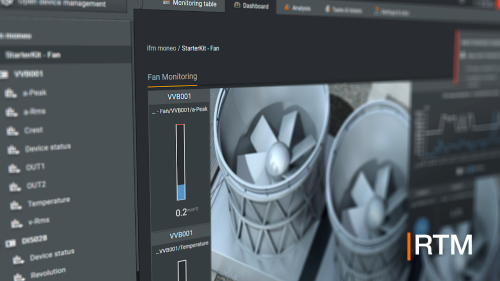

The implementation: level monitoring with moneo RTM

Thanks to the existing IT structure, moneo was installed on a central server of ifm prover gmbh to activate the moneo RTM module. The level sensors for tank monitoring are connected to an IO-Link master that in turn is connected to the server via a VLAN.

The successes achieved so far: the advantages of level monitoring with moneo RTM

Level monitoring with moneo RTM has led to a more reliable and uninterrupted calibration process. Thanks to the automated notification function when the limit value is about to not be reached, the water demand can be covered permanently, thus reducing the cost factor of calibration. Another result of automated level monitoring is the stable assurance of high product quality based on consistently ideal process conditions.

Bottom line: These features and services of moneo RTM provide added value in level monitoring

- Calculated values: Sensor values can be converted to process-relevant information with the help of data modelling

- Cockpit functions: comprehensive and individual visualisation of all sensors in the process

- Detailed information about levels by capturing sensor values

- Integrated alarm management: Fast reaction to changing process parameters

- Analysis: increase of levels according to the requirements by means of targeted evaluation of historical data

- Identification of limit values that are exceeded or not reached

System setup

- IO-Link master

- Continuous level sensor (guided wave radar)

Dashboard

The moneo dashboard provides a clear overview

The dashboard provides the user with an overview of the relevant process values for the calibration plant.

- Current tank level in mm

- Current tank level in litres

- Lacking water quantity in litres

- Traffic light display for the warning and alarm values of the level

Analysis

Via the analysis function, the user can analyse the tank level in detail. The level values are permanently recorded and can even be checked after days, weeks or months. This allows, for example, to draw conclusions about leaks.

Tasks & tickets: managing limit values

For the two level sensors, values for the lower and upper alarm limits are defined on the basis of maintenance experience.

Calculated values kalkulierte Werte

The following values are calculated additionally based on the level.

Current tank level in litres

Since the floor space of the tank is known to be 0.24 m², the fill quantity can be easily determined by using the formula "floor space * level".

- Current tank level in mm

- Floor space of the tank

- Multiplication of floor space and level

- Volume in litres as result of the calculation

Lacking water quantity in litres

Since the maximum volume of the tank is known to be 72 litres and the current fill quantity has already been calculated, the missing quantity can easily be determined via "maximum volume - fill quantity".

- Current tank level in mm

- Floor space of the tank

- Subtraction of floor space and level

- Volume in litres as result of the calculation