- moneo: IIoT platform

- Use cases

Optimised maintenance of wear parts at a final test station with moneo RTM

Change of maintenance strategy towards condition-based maintenance at ifm prover gmbh

Product quality is a significant success factor for ifm. For the purpose of quality control, a final inspection of pressure sensors is carried out at various workstations at ifm prover. Different types of production equipment are used. In some cases, electrical contact between the production equipment and the tested pressure sensors is established via an M12 connector. The constant friction caused by connecting the sensors results in wear of the socket on this connector. Consequently, the production equipment must be replaced regularly.

The initial situation:

In the case of the M12 connectors used as production equipment, the sockets were replaced at fixed time intervals, i.e., either prematurely or too late. The actual quantity produced was not considered. Production equipment would fail and cause unplanned process standstill, resulting in cost increases. No further analysis took place.

Aim of the project:

Shift from a time-based maintenance strategy to a needs-driven replacement of wear parts by means of piece counting. For this purpose, the lifting and closing operations are to be detected using position sensors. When a limit value is reached, a corresponding information (alarm) is to be generated so that the production equipment can be replaced in time.

Implementation:

Due to the existing powerful IT infrastructure, moneo was installed as Windows installer on a central server of ifm prover gmbh to activate the moneo RTM module.

The VSE101 diagnostic electronics from ifm’s broad automation portfolio was chosen as a suitable component.

Position sensors and inductive sensors were used to detect the stress. The cycles are read by the position sensors. On the knuckle-joint press, an inductive sensor detects the lever position and another sensor detects the position of the protective cover. The process values provided by both sensors allow conclusions to be drawn about the quantities of compressed air sensors produced at the workstations.

The result:

Advantages of monitoring the produced quantities with moneo RTM

The change in maintenance strategy from time-based to quantity-based maintenance was successfully implemented. The entire process was optimised through this. The production equipment is only replaced if wear and tear makes this necessary. This has a positive impact on the use of resources in maintenance as well as on product quality, as the test is carried out with fully functional production equipment. As a result, rejects are avoided, resources better used and costs saved.

Bottom line:

These features and services of moneo RTM provide added value in monitoring the produced quantities:

- Conversion of sensor values into process-relevant information using data modelling – calculated values

- Detailed visualisation of all sensors in the process by means of individual dashboard function

- Detailed information about filter states by capturing sensor values

- Fast reaction to changing process parameters through integrated alarm management

- Needs-based replacement of filters thanks to targeted analysis of historical data and reduction of resource use

- Identification of limit values that are exceeded or not reached

System setup with VSE

- VSE diagnostic electronics for vibration sensors

- Inductive sensor

- Key-operated pushbutton for counter reset

Dashboard

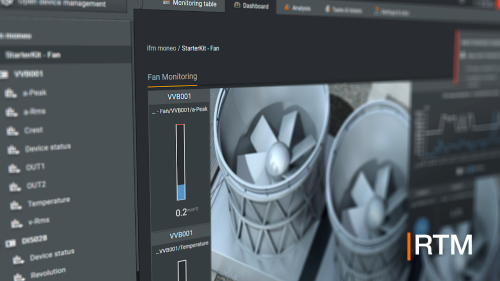

The moneo RTM dashboard visualises the processes of all connected sensors. It provides the user with an overview of all relevant process values for this plant.

- Current count (insulation test)

- Traffic light display of the warning and alarm values (insulation test)

- Traffic light display of the warning and alarm values (leak test)

- Current count (leak test)

Tasks & tickets: manage thresholds

In this application, individual thresholds are defined for all process values using moneo RTM. When they are reached, the maintenance staff is automatically notified via email and can schedule the replacement accordingly.

It is also possible to define a warning threshold. When this threshold is reached, the staff is again automatically notified via email about the required replacement. Now the parts must be replaced at the latest.

- Upper warning threshold

- Upper alarm threshold

Manage ticket processing rules

The ticket processing rules wizard allows users to easily define warning and alarm rules. In this application, a group of email recipients in the maintenance department is notified when the warning threshold is reached.

An additional rule notifies the responsible production staff when the alarm threshold is reached.

- Definition of thresholds (5) and data sources (6)

- Defines which rule is applied

- Defines the warning or alarm urgency

- Defines the email recipients

- Definition of the relevant thresholds

- Definition of the corresponding data sources

The email generated from within moneo already contains ticket information:

- Affected data source

- Value that was exceeded or not reached

- Ticket priority

- Timestamp