Discover the product range now

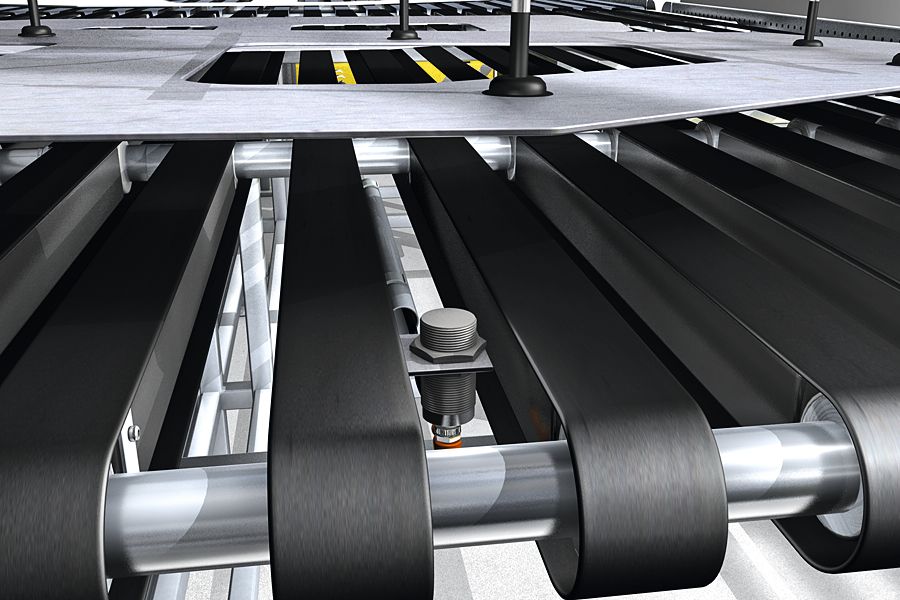

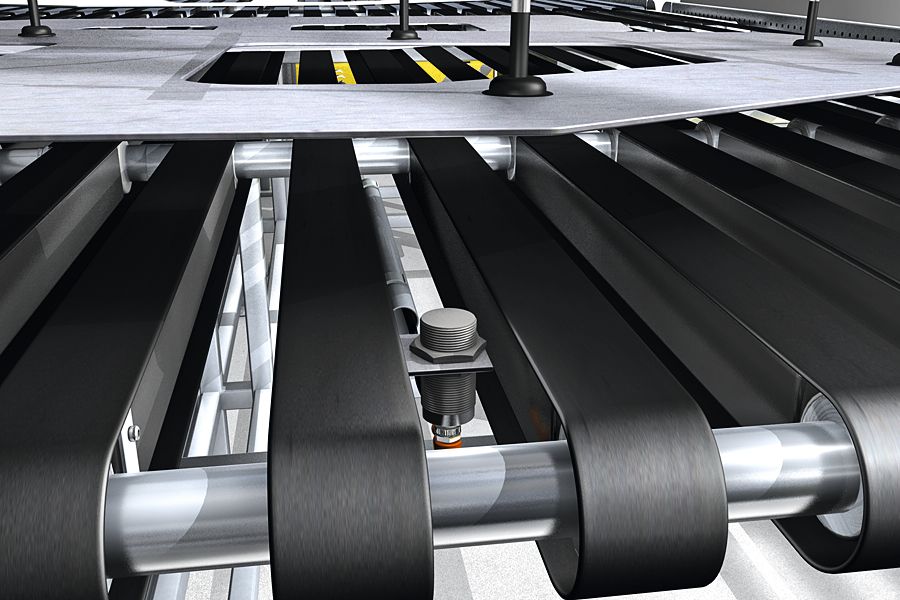

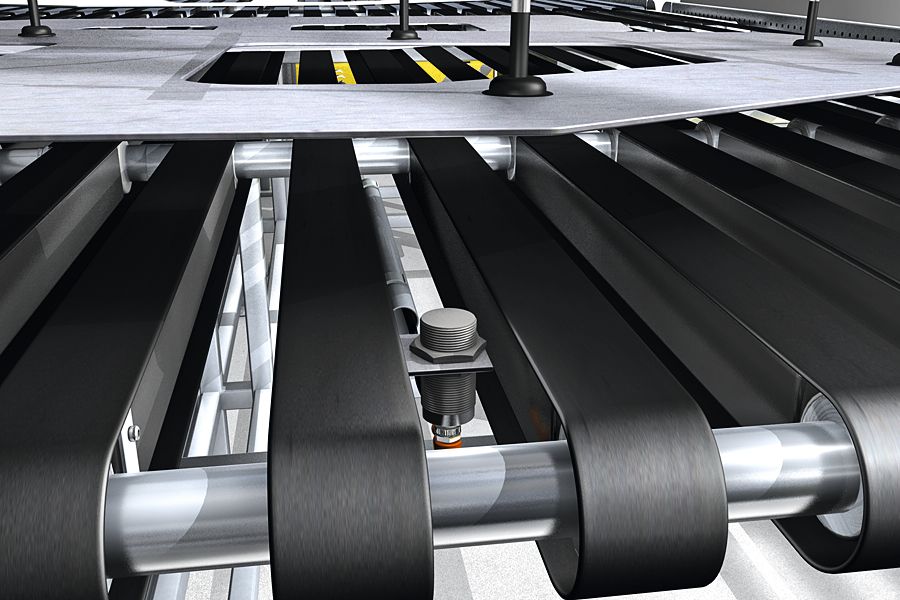

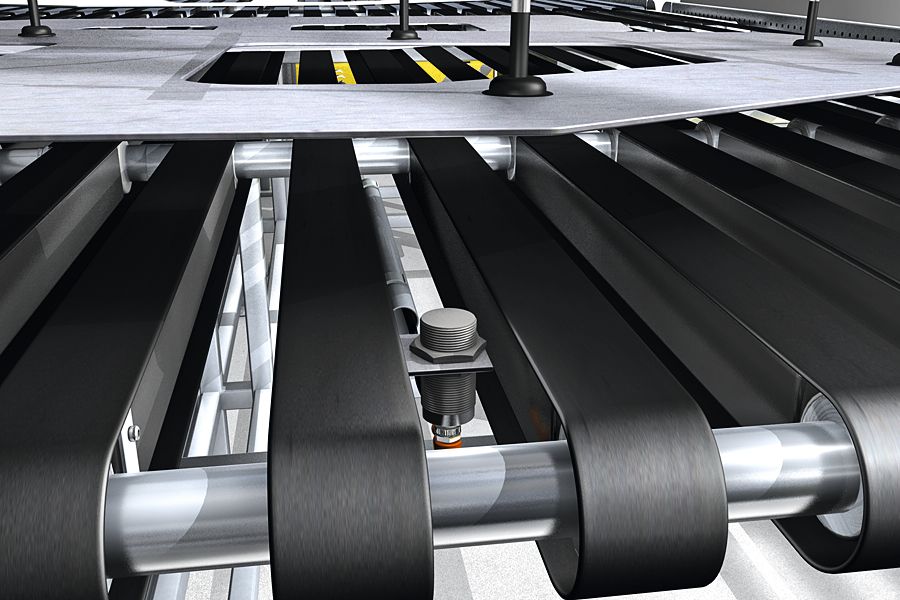

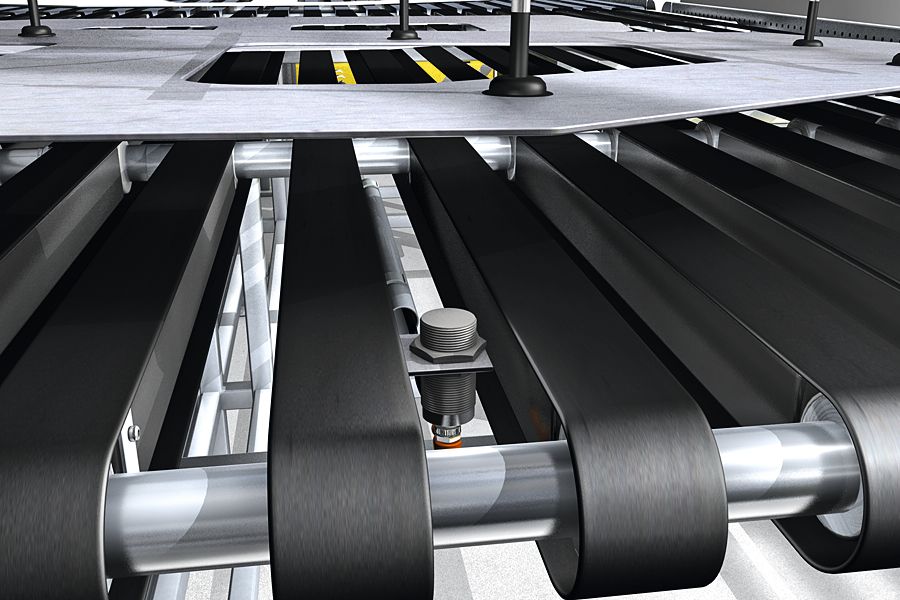

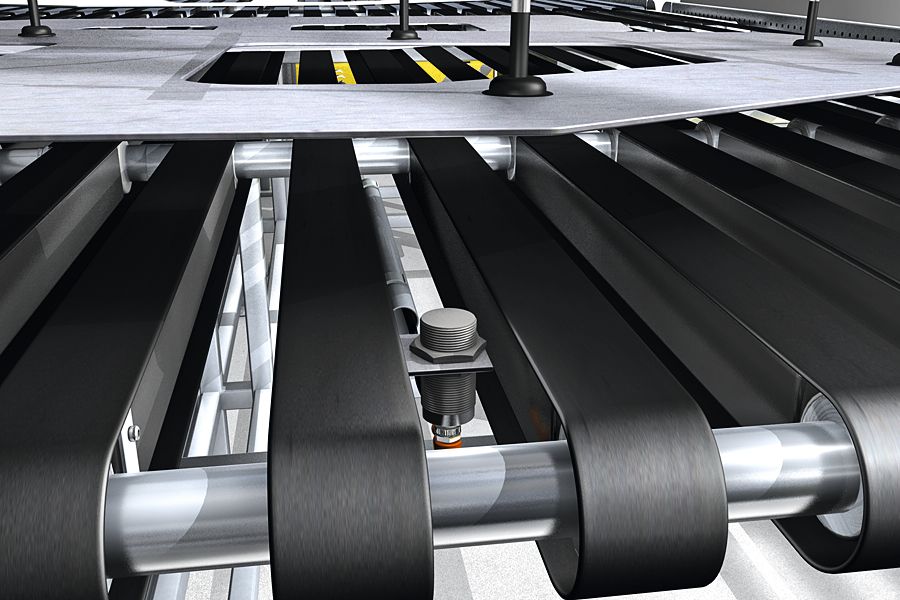

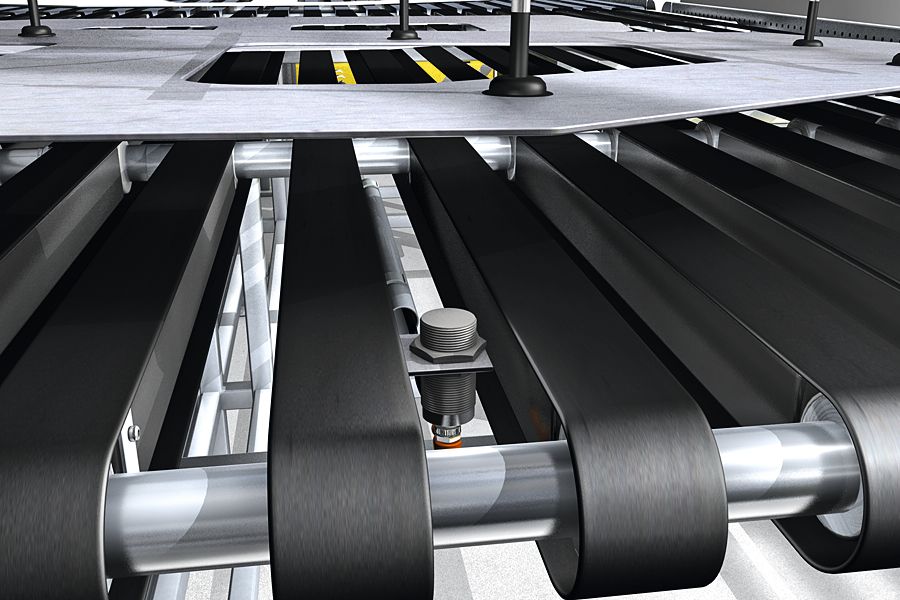

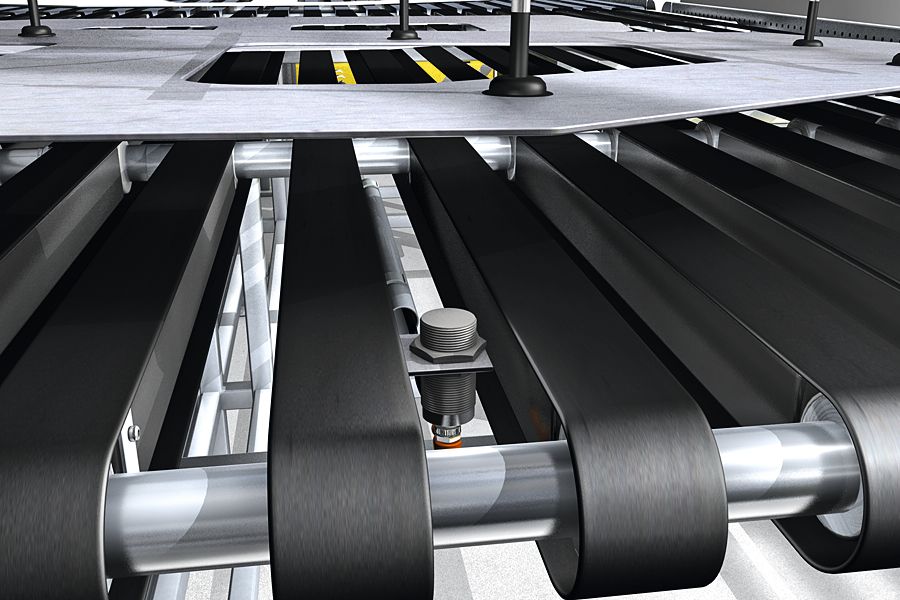

Position sensors

Process sensors / Fluid sensors

Condition monitoring

Experience our latest innovations and proven hardware and software products for effective digitalisation at Hannover Messe 2024 – from sensor to cloud!

Request your ticket nowMore than a third of global CO2 emissions are caused by energy production alone. Around 40 per cent of this energy is consumed by industry.

Watch the latest episode now.Experience the new ease of IO-Link parameter setting with our moneo configure free software at no charge: automatic device recognition, easy data set management and much more.

Download moneo configure free nowFood production must be sustainable, efficient and safe, now and in the future. How does ifm support its customers in meeting these challenges? Find out in our new food magazine.

Discover now!